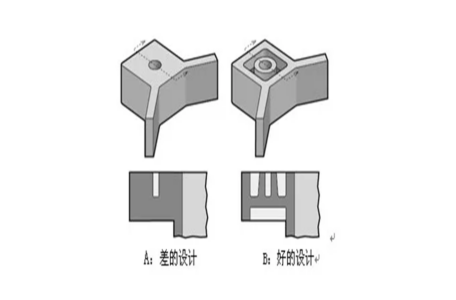

The whole process of a product from research and development to the market needs to go through many links, among which the product structure design is an important part. In terms of product structure, the product must be manufactured and mass-produced with a mold for the product, and a plastic mold for plastic parts. Therefore, a product structure design engineer must not only be familiar with the structure of plastic parts, but also have a certain understanding of plastic molds. Today I will share with you 14 key points of plastic product structure design~

Blog

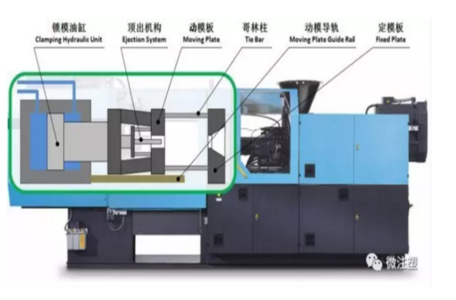

Injection molding machine clamping parameters setting

Start clamping 1. Start clamping pressure: The initial setting value is 25. When the pressure is too small and the speed is too slow, you can try to increase the speed. This pressure is too small, and the speed cannot be increased to the speed when needed. The speed is increased by +5 each time. Try and pay attention that when the pressure is set to a large value, the movable template will be instantly increased by high pressure to change the static state and become moving, so that the movable template hole and the tie rod will generate huge friction, which will accelerate the wear of the machine’s movable template hole and tie rod for a long time. The stability and precision of the movement of the movable platen decreases, which may affect the production of individual molds with higher precision requirements for the clamping mechanism.

Introduction to the processing technology of crystalline plastics

The crystallinity and crystal form of crystalline plastic affect the physical and mechanical properties of the product. If the cooling rate during molding is slow, it is conducive to the progress of crystallization and can increase the degree of crystallinity. Therefore, it is extremely important to control the mold temperature to obtain products with excellent mechanical properties and good surface gloss.

The main factors affecting the processing accuracy of plastic molds

1. Dimensional accuracy refers to the degree of conformity between the actual size of the processed part and the center of the tolerance zone of the part size. The dimensional accuracy is controlled by the dimensional tolerance. The dimensional tolerance is the allowable amount of variation in the size of the part during mold processing. In the case of the same basic size, the smaller the dimensional tolerance, the higher the dimensional accuracy.

Essential skills for plastic mold machining and repair personnel

How can plastic machining service factories increase brightness when producing abs injection molded parts?

The main reason for the defects in plastic service machining in the production of plastic parts is the injection of molds, industrial raw materials, etc. If the mold machining is poor, such as scars, wear, roughness, etc., it will also be reflected on the plastic parts, and the plastic parts will be shiny. bad. In this regard, the plastic service machining plant must carefully process the mold to ensure that the surface of the mold cavity is not rough, and if necessary, the mold can be polished and chrome-plated.

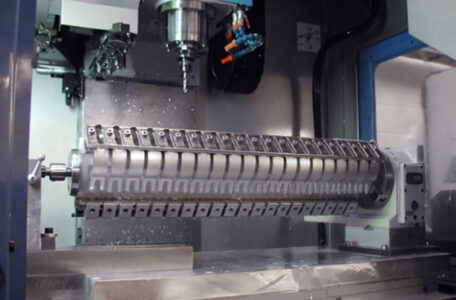

CNC machining precautions pay attention to safety details

In the process of precision cnc machining, every job is a problem that needs attention, especially in the case of precision CNC machining, the details of the processing process are very important. Only in this way can we get good practical results under the working conditions. So what details should be paid attention to in precision CNC machining? 1. Before machining precision CNC parts, check whether a part of the machine is filled with lubricating oil before working, then start and check whether the clutch and braking system are all normal, and run the machine idling for 1-3 minutes. When the machine has common failures Prohibit actual operation.

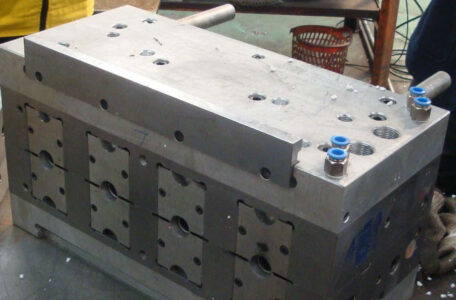

Production management of plastic molds

First, the effective management of product data management, process data management, drawing document management: effective mold product data management, process data management, drawing document management, can ensure the comprehensiveness of the document, the consistency of the drawing version; Drawings can achieve effective sharing and effective query utilization. A complete file management computer database can be established, and the design drawings accumulated by the design department, scattered, previously scattered and isolated information can be organized and used to prevent 2d, 3d confusion due to design drawings, original, design changes, and maintenance versions Confusion, 3D model and 2D drawing data inconsistency, 2D drawing design is not standardized and chaotic, which causes problems that are not easy to be discovered and corrected in time, causing molds to be modified and reworked, or even obsolete, increasing mold manufacturing costs and lengthening mold manufacturing The production cycle affects the delivery period.

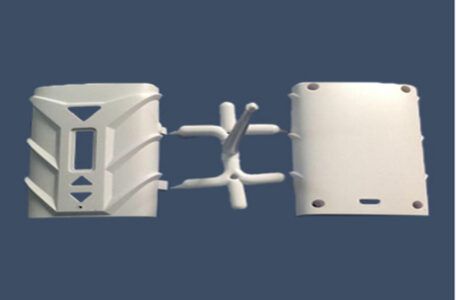

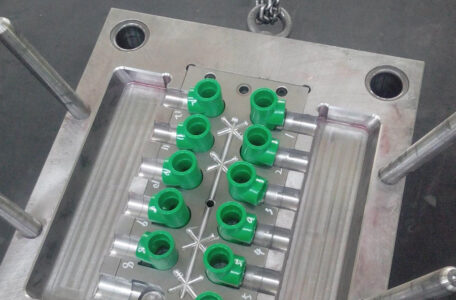

Introduction of three types of plastic molds

Plastic molds are tools used with plastic molding machines in the plastic processing industry, and can provide complete structural configurations and precise dimensions for plastic products. According to different molding methods, plastic molds can be divided into the following three types. 1.Injection mold Injection molds are often used to produce thermoplastic parts, and the corresponding processing equipment is injection molding machines.

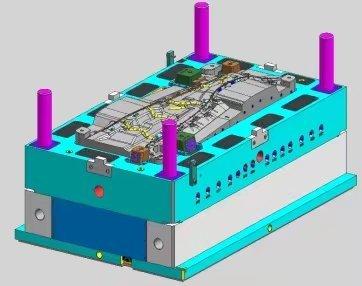

Seven Components Of Injection Mold

The basic structure of the injection mold can be divided into seven parts according to its use function: molding parts, pouring system, guiding mechanism, ejection device, lateral parting and core pulling mechanism, cooling and heating system and exhaust system. Molded parts It refers to the parts that make up the mold cavity.Mainly include: punch, die, core, forming rod, forming ring and inserts and other parts. The pouring system refers to the plastic flow channel in the mold from the nozzle of the injection molding machine to the cavity.Ordinary pouring system is composed of main runner, branch runner, gate, cold slug hole and so on.

- ABS Machining

- Ceramic Machining

- PA6 Machining

- PAI Machining

- PC Machining

- PCTFE Machining

- PEEK Machining

- PEI Machining

- PET Machining

- PI Machining

- PMMA Machining

- PP Machining

- PPS Machining

- Teflon Machining

- PU Machining

- PVC Machining

- PVDF Machining

- UHMW Machining

- UNILATE Machining

- POM Machining

- PTFE Machining

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal

- Research and Analysis of the Recent Development of the Electronic Accessories Market

- Trends that the hardware mold industry needs to understand to keep up with the international pace

- Inventory of new trends in auto parts technology

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal