The plastic injection mold production process is generally divided into: customer customization, mold design, mold manufacturing, mold inspection and testing, mold modification and repair, mold maintenance, and I will explain them one by one below.

Customer Customization

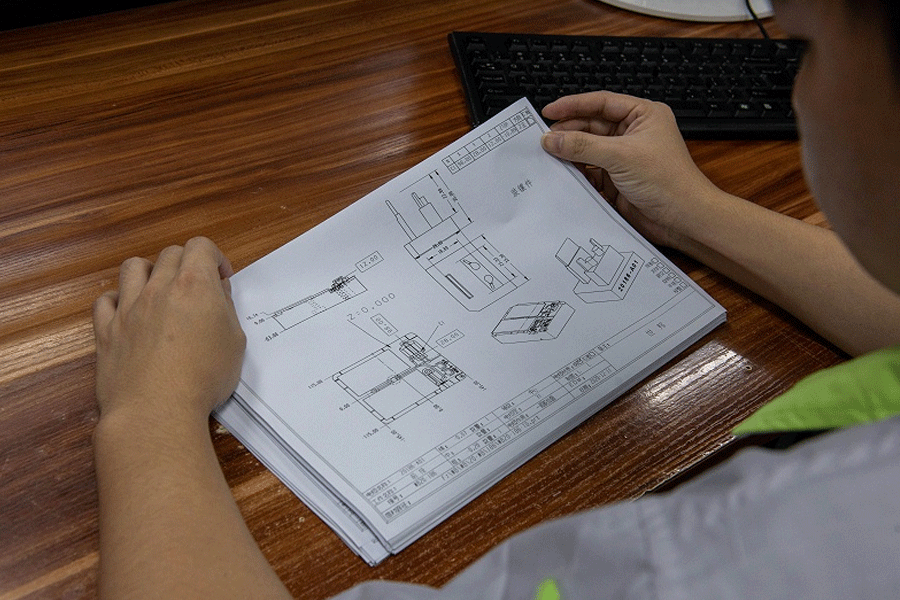

In the production of plastic molds, customer engineers first provide product drawings to the mold manufacturer. The manufacturer collects, analyzes, and digests product data through the task requirements of molded plastic production, which is customized for customers.

1.Plastic parts production requirements

Understand technical requirements such as the purpose, manufacturability, and dimensional accuracy of the parts For example, what are the requirements for plastic parts in terms of appearance, color transparency, and performance, whether the geometric structure, slope, and inserts of the plastic parts are reasonable, the allowable degree of molding defects such as weld marks and shrinkage holes, and whether they are coated or not. Post-processing such as installation, electroplating, silk-screening, and drilling.

Estimate whether the molding tolerance is lower than the tolerance of the plastic parts, and whether the plastic parts meeting the requirements can be molded. In addition, it is necessary to understand the plasticization and molding process parameters of plastics.

2.Process information

Understand the requirements of glue feeding method, beer machine model, plastic material performance, mold structure type, etc.

The molding material should meet the strength requirements of plastic parts, and have good fluidity, uniformity, isotropy, and thermal stability. According to the purpose of the plastic part and whether it is post-processed, the molding material should meet the requirements of dyeing, metal plating, decorative performance, necessary elasticity and plasticity, transparency or reflection performance, adhesiveness (such as ultrasound) or weldability.

3.Choose molding equipment

Injection capacity, clamping pressure, injection pressure, mold installation size, ejection device and size, nozzle hole diameter and nozzle spherical radius, gate sleeve positioning ring size, mold maximum thickness and minimum thickness, template stroke, etc.

4.The specific structure of the mold

Two-plate mold, three-plate mold. Whether the mold structure is reliable, whether it meets the process technology of plastic parts (such as geometric shape, indicating finish and dimensional accuracy, etc.) and production economic requirements (low part cost, high production efficiency, continuous work of the mold, long service life, and labor saving Wait).

Mold Design

1.Plastic parts ranking

Positioning of plastic parts refers to arranging one or more plastic parts according to a reasonable injection molding process and mold structure according to customer requirements.

The ranking of plastic parts complements the mold structure and the plastic processability, and directly affects the later injection process. The corresponding mold structure must be considered when ranking, and the ranking must be adjusted under the conditions of meeting the mold structure.

From the perspective of injection molding process, the following points need to be considered:

- a. The length of the runner;

- b. Runner waste;

- c. Gate location;

- d. Glue feeding balance;

- e. The cavity pressure is balanced.

- From the perspective of mold structure, the following points need to be considered:

- a. Meet the requirements of sealing glue

- b. Meet the space requirements of the mold structure: shovel base, row position, inclined top and other space requirements, whether the mold structure is strong enough, whether multiple moving parts interfere, and the position of the cylinder should avoid the position of the top stick hole.

- c. Fully consider the screw, cooling water and ejector device: For the arrangement, pay attention to the influence of the screw and the ejector pin on the cooling water hole.

- d. Whether the mold length and width ratio is coordinated: the mold is as compact as possible, the length and width ratio is appropriate, and the installation requirements of the injection machine should be considered.

2.Drawing and ordering of quotation chart

- a. The quotation drawing is the initial design plan of the mold, and also provides reference instructions for the mold ordering. The quotation chart is a relatively detailed identification of the mold embryo and its structure and the size of the mold meat based on the original layout.

- b. Material ordering is based on the quotation drawing, drawing a sketch of the die blank and filling in the order form.When ordering materials, attention should be paid to selecting various mold materials according to the various requirements of the mold.

3.Mould structure design

The mold structure is determined by the type of injection machine and the characteristics of the rubber parts. The design focuses on the following aspects:

- Technical specifications of the injection molding machine;

- Process performance of plastic;

- The pouring system, including runners, gates, etc.;

- Molded parts;

- Common structural parts;

- Position organization;

- Ejector mechanism;

- Mold temperature control;

- Exhaust;

- Mold material.

Mold design needs to comprehensively consider various factors, select a reasonable structure form, and meet the purpose of mold forming.

a.Plastic Parts Ranking

In the 3D design stage, the ranking is now based on the 2D ranking at the beginning of the design to do more in-depth design.

b.Parting

Choose the correct parting surface, consider the sealing distance, build a reference plane, balance the lateral pressure, flatten the nozzle face, and deal with the penetration of small holes, avoid sharp steel, comprehensively consider the appearance of the product, etc. to be considered.

c. Check And Improve The Strength Of The Mold

In order to ensure that the mold can work normally, it is necessary to check not only the overall strength of the mold, but also the strength of the local structure of the mold.

Make certain improvements to specific institutions to increase local strength:

d. Design Of Mold Parts

Mold parts can be divided into forming parts and structural parts according to their functions. Forming parts refer to structural parts that directly participate in the formation of cavity space, such as concave mold (cavity), convex mold (core), inserts, row positions, etc.; structural parts refer to installation, positioning, guidance, and ejection And the parts that complete various actions during forming, such as positioning ring, pump nozzle, screw, pull rod, thimble, sealing ring, fixed distance pull plate, pull hook, etc.

The disassembly of inserts mainly considers the following aspects:

- Cannot produce sharp steel or thin steel

- Easy to process

- Easy to resize and maintain

- Ensure the strength of molded parts

- Easy to assemble

- Do not affect the appearance

- Comprehensive consideration of cooling (partial cooling is difficult after the insert is made, and the cooling situation should be considered)

In the design of structural parts, the layout of the thimble and the layout of the water transportation generally follow the principle of first arranging the thimble, then arranging and transporting the water, and then adjusting the thimble. However, in the actual production process, the situation of mold modification is often considered. After the mold is completed, water transportation is not started immediately, and the mold can only be opened after the modification is completed for a certain amount of time.

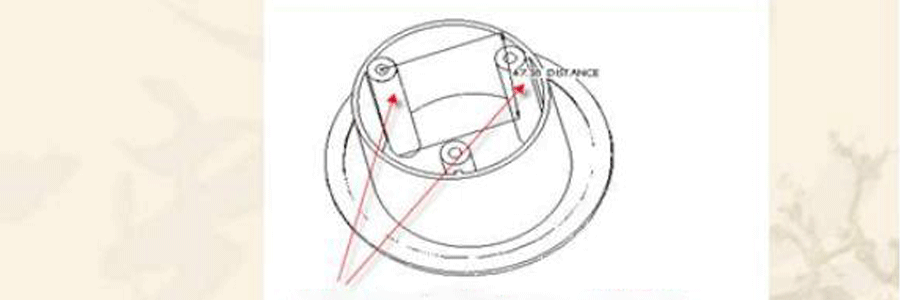

The layout of the main tube: The main tube is generally used for forming column positions. In addition, for the deep bone position, the thimble is easy to be white when ejected, and the main tube can also be added with bone to assist the ejection. Under normal circumstances, the wall thickness of the cylinder is >=1mm, and the cylinder and cylinder needle are ordered together when ordering.

In the structural design, the height of the column should not be too high as much as possible, otherwise the cylinder needle is easy to bend and difficult to eject, as shown in the figure below.

For the design and selection of other structural parts, such as positioning rings, pumps, screws, pull rods, sealing rings, fixed distance pull plates, pull hooks, springs, etc., if you are interested, you can find some information to understand by yourself.

e. Production of mold drawings

The mold drawing is an important document that transforms the design intent into the mold making. Generally, it needs to be drawn in accordance with national standards, and it also needs to be combined with the customary drawing methods of each factory.

The mold drawing includes the general assembly structure drawing and its technical requirements, and there are also parts drawings of all parts including various inserts.

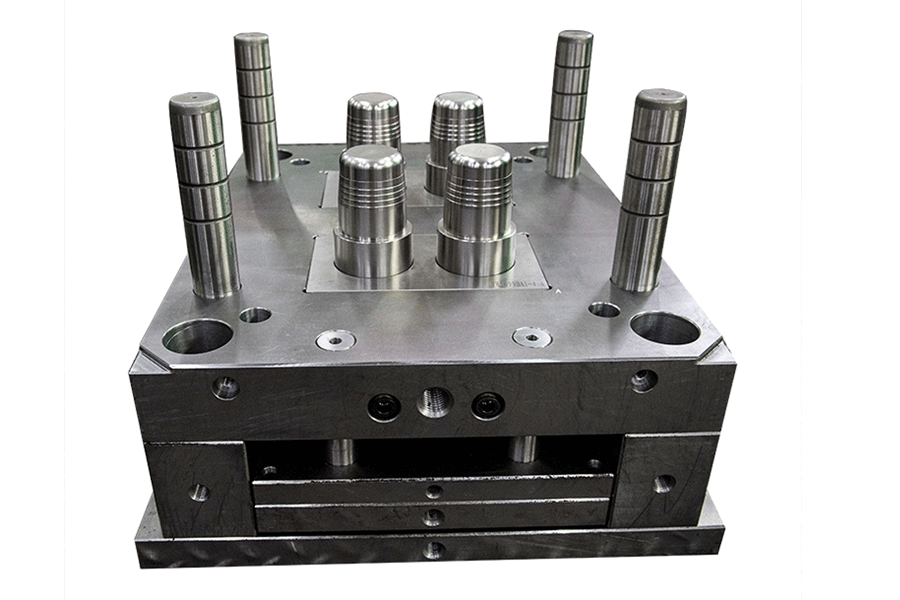

Mold Manufacturing

1.Compile the program and disassemble the electricity

After the mold design is completed, the CNC program must be compiled according to the processing conditions of each part and whether it needs to be disassembled and processed by EDM.

2.Cnc Machining

The mechanical processing of the mold includes CNC processing, EDM processing, wire cutting processing, deep hole drilling processing and so on. After the mold base and materials are ordered, the mold is only in rough machining state or only steel material. At this time, a series of mechanical processing must be carried out according to the design intent of the mold to make various parts.

CNC machining, computer numerical control, that is, CNC machining, its requirements include various processing procedures, tool selection, processing parameters and so on. Those who are interested can find relevant materials to learn.

EDM machining is electric discharge machining, which is a machining process that uses electrical discharge corrosion materials to reach the required size, so only conductive materials can be processed. The electricity used is generally copper and graphite.

Wire cutting is used for processing sharp corners.Deep hole drills are generally used in the processing of large mold water-carrying holes and the processing of thimble barrel holes.

3.Fitter assembly

The fitter plays a very important role in the mold making process, and the work needs to run through the entire mold manufacturing process. The fitter’s work, fit mold assembly, car milling and drilling are all proficient.

4.Saving mold and polishing

Mold saving and polishing are the processing of mold parts using sandpaper, oilstone, diamond paste and other tool materials after the mold is processed by CNC, EDM, and fitter, and before the mold is assembled.

Mold Inspection And Test Mold

1.Inspection of the mold

The mold and assembly process is actually a mold inspection process. In the fit mold assembly, you can check whether the red lead is in place, whether the thimble cylinder is smooth, and whether the mold has any mistakes or interference.

2.Tryout

After the mold is manufactured, in order to check the condition of the mold and whether the structure of the rubber part is completed, the injection machine needs to be tested. Through the trial mold, you can understand the situation of the mold in the process of beer production and whether the structure of the rubber part is completed.

Refer to other materials for the requirements of mold trial and the improvement of plastic defects.

Modification and Modification

After the mold is tested, corresponding changes shall be made according to the conditions of the test mold. In addition, after the engineer confirms the plastic part, the structure of the plastic part must be changed accordingly.

Since the mold has been made, all changes are more troublesome, sometimes even more difficult than redoing. The best way to change must be found according to the specific situation.

For structural design, it is necessary to understand the mold situation as much as possible to change the structure, whether it is water, thimble, how to change it is easy, etc. You can make relevant changes in combination with relevant information. If necessary, you can consult the mold team colleagues .

Processing of cooling system:

Cooling system processing (drilling and transporting water), products generally require that the front mold transport water needs to be processed when the first mold modification data is issued, and the rear mold transport water needs to be processed after the second mold modification data is issued, but it is open for water transportation. Whether or not it has a greater impact on beer production, such as PC-based beer production (requiring hot oil beer), try to open it before the first trial.

Therefore, various conditions should be considered in the structural design drawing stage, and the workload of mold modification should be minimized, so that the opening of the water transport can operate normally, and the size of the beer can be determined as soon as possible.

Modification of the product structure: adding bones, adding pillars, remodeling the structure and redoing inserts. Adding and subtracting glue to the original bone, shifting the column, increasing or decreasing the screw column, increasing the height and decreasing the height, trimming the front and so on.

Mold Maintenance

Because the mold works under high temperature and high pressure and is in contact with air for a long time, it is easy to rust. Therefore, the mold needs to be maintained. When not working, it needs to be painted with anti-rust oil and butter.

In addition, because the mold steel has a certain service life and the design of the mold structure is unreasonable, some sharp and thin steel structures or tube thimbles may crack and break, and they must be maintained and repaired continuously in the later maintenance.