Compared with the development level of foreign 3D printing technology, there is still a certain gap in our country, but don’t be discouraged, we also have our strengths and advantages in this industry.

The research on china 3D printing technology started as early as the early 1990s. System of Chinese Academy of Sciences. At present, these universities are still the research centers of 3D printing technology in my country. Among them, Huazhong University of Science and Technology has the advantage of laser powder unsintering technology, Tsinghua University focuses on plastic accumulation technology and biomedical fields, Beihang University and Northwestern Polytechnical University mainly focus on In the field of metal Jinan 3D printers, Xi’an Jiaotong University mainly focuses on the field of photocuring in the whole field of 3D printing, and the development at home and abroad is also similar.

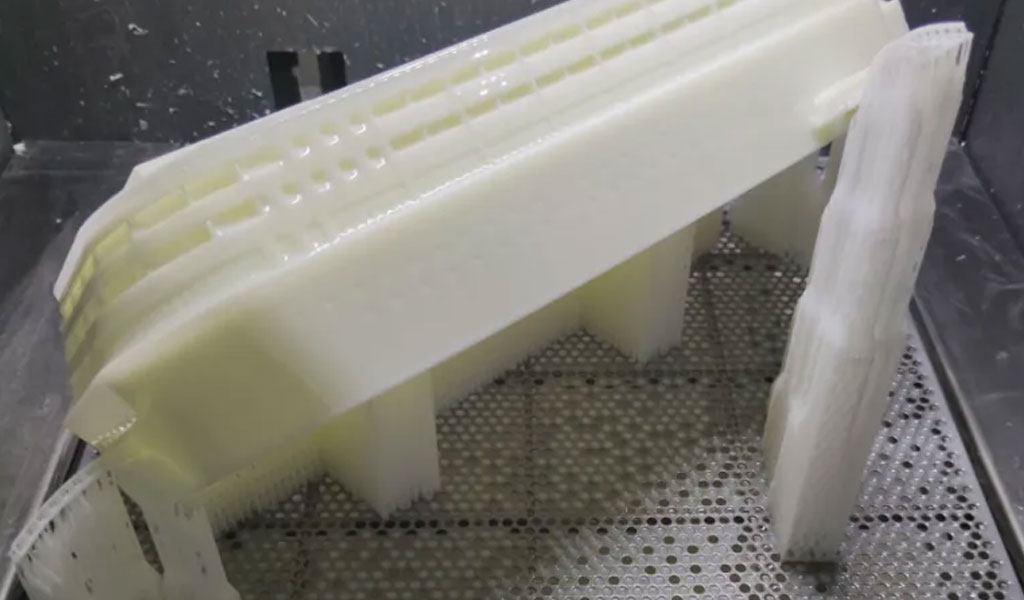

In terms of equipment production, the functions of 3D printer equipment produced in my country are close to the level of international counterparts, and the difference between the two is mainly reflected in the reliability of equipment and material research and development. For example, some key components of china dlp 3D printing, such as laser heads, need to be imported from abroad. In addition, my country is far less abundant than the United States and Germany in terms of material quality and variety, and many experimental materials used for research and development also need to be imported. The gap is reflected in the application.

In foreign countries, sla 3D printing technology has been widely used in new product development, biomedicine, aerospace, film and television education, cultural creativity, etc., while my country is still limited to a few fields such as mold models and cultural creative products. In western countries, Jinan Custom 3D Printing technology can be used to print personalized dentures and prosthetics, which has achieved results in the field of medical and health. However, “fake” things do not satisfy people. A frontier direction of future 3D printing technology is to study how to print “living” human body “parts”. As long as the active materials compatible with the human body can be found, the meshes can be printed, and the cells of the human body can be cultured, and the real human tissue can be produced. However, the current printing of human organs is only a scientific vision, which relies on breakthroughs in printing materials and technologies, and requires interdisciplinary research in biology, medicine, and computers.

Although there is still a certain gap between us and foreign countries, there is no need to be pessimistic. We must fully integrate advantageous resources, organically The Development Of 3D Printing In China technology with traditional industries, and expand the application space of 3D printing technology. In this way, there is also a chance to catch up. We still need to do a lot of basic work. One of the biggest advantages now is that the penetration rate of 3D printing in China is relatively high, far exceeding that of the United States. In June 2013, I was invited to visit the United States. When I communicated with several universities in the south of sls 3D printing, their teachers had not heard of the price list of 3D printers, which made me unable to believe it. Almost everyone in China is talking about 3D printing. Everyone knows about 3D printing. Of course, many people only know the concept. Popularization requires a process, and on the basis of popularization, precise positioning is also required.

Although there is still a big gap, fdm 3D printing technology is already one of the technologies that has a small gap between my country’s manufacturing industry and foreign advanced levels. Some fields are almost synchronized or surpassed, and in some aspects, it also has its own characteristics and certain advantages. We have our strengths, we must have enough confidence.