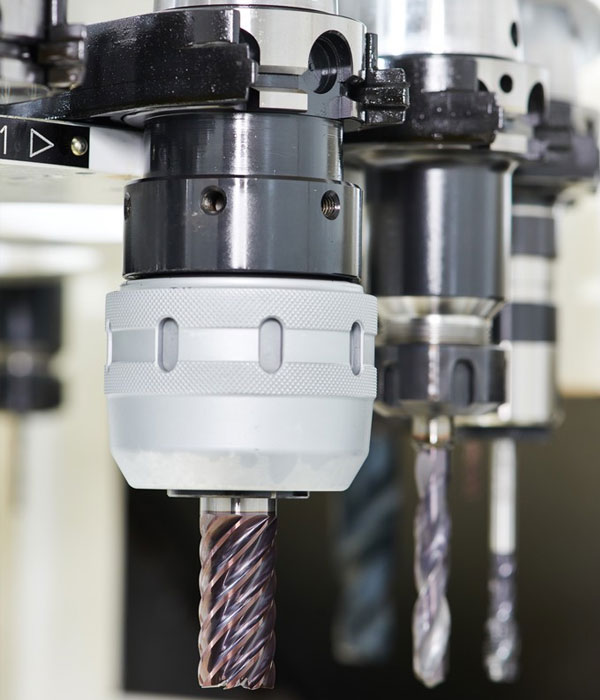

PTFE Machining

PTFE Material or Teflon®, is Polytetrafluoroethylene which is a synthetic fluoropolymer of tetrafluoroethylene. Within Industry PTFE is well known and widely used, in numerous applications.PTFE Machining –BE-CU teflon cnc machining shop Bespoke PTFE Machined Parts to customer specifications, samples or drawings. Our Plastic CNC Machine shop specifically caters for Industrial Engineering Plastic Materials, such as PTFE.

BE-CU.COM is China’s leading professional polytetrafluoroethylene (PTFE) and ultra-high polymer (UPMWPE) CNC processing manufacturer.

We not only have advanced production equipment, but also have professional technical engineers to provide a full range of technical support and services. Our products have successfully entered the international market and are exported to more than 40 countries such as the United States, South Korea, India, the Philippines, Russia, Saudi Arabia, Indonesia, etc. nation.

For the dispersive machining teflon resin, carry out the calendering process; take advantage of the low cohesion and fibrillation properties of this resin, add the PTFE aqueous emulsion to the powder system, stir for a certain period of time, the PTFE fibrils are entangled in the powder, and then Compression to make the powder into a solid, and calendering the solid to obtain a PTFE filled and modified film.

Using the characteristics of low hardness and good toughness of machining PTFE sintered products, metal turning is carried out. The thickness of the PTFE film processed by turning can reach about 0.04mm. This film has good mechanical properties, does not add any substances during machining, has low impurity content and is non-toxic, and can be used in the optical field.

In addition, there is a conventional extrusion method and a calendering method for extrusion machining, and the resin is directly processed with raw materials without melting and plasticizing. This method utilizes the residual deformation characteristics of PTFE under the action of compressive force, and the residual deformation can also be increased by adding human-fixing aids. Usually, the PTFE material with the addition of extrusion aids is pressed into a certain density. , Put it in the extruder and heat it properly, after extruding thin strips, it is finally sent to the calendering roller to be calendered into a film.

In addition to the one-time machining technology introduced above, PTFE machining also has some newly developed secondary machining technologies worthy of attention, such as PTFE vacuum forming technology, hot press forming and hot blow molding technology, isobaric forming machining technology, etc.

copper powder filled PTFE, make full use of my country’s rare earth resources, and develop new varieties of rare earth filled PTFE and nano-modified PTFE will be the key research direction in my country in the future