Polyetheretherketone is a linear aromatic polymer compound containing chains in the main chain of the molecule. Its structural unit is oxygen-p-phenylene-oxy-carbonyl-p-phenylene, which is semi-crystalline and thermoplastic. Polyetheretherketone has the heat resistance and chemical stability of thermosetting plastics and the molding and machining peek of thermoplastics. Polyetheretherketone also has excellent heat resistance. The heat distortion temperature is 160°C, and when reinforced with 20% to 30% glass fiber, the heat distortion temperature can be increased to 280 to 300°C. The thermal stability of polyether ether ketone is good, 420 ℃ in air. The weight loss is only 2% at 2h, 2.5% at 500°C, and significant thermal weight loss occurs only at 500°C. The electrical insulating properties of ether ether ketone are very excellent, and the volume resistivity is about 10-10 ω·cm. It still has a small dielectric constant and dielectric loss in the high frequency range. The chemical stability of polyether ether Read more

Blog

The Development Of 3D Printing In China

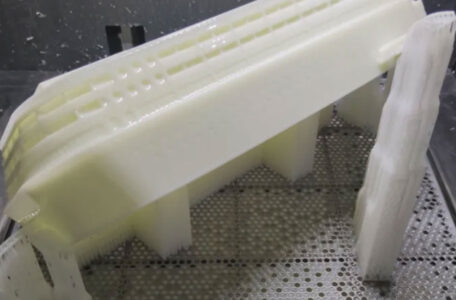

Compared with the development level of foreign 3D printing technology, there is still a certain gap in our country, but don’t be discouraged, we also have our strengths and advantages in this industry. The research on china 3D printing technology started as early as the early 1990s. System of Chinese Academy of Sciences. At present, these universities are still the research centers of 3D printing technology in my country. Among them, Huazhong University of Science and Technology has the advantage of laser powder unsintering technology, Tsinghua University focuses on plastic accumulation technology and biomedical fields, Beihang University and Northwestern Polytechnical University mainly focus on In the field of metal Jinan 3D printers, Xi’an Jiaotong University mainly focuses on the field of photocuring in the whole field of 3D printing, and the development at home and abroad is also similar. In terms of equipment production, the functions of 3D printer equipment Read more

Advantages Of 3D Printing Technology In China

As the world’s factory, China naturally has advantages that other countries do not have, such as domestic 3D metal printing technology, so how good is China 3D printing Service? Its importance is not lost to the lithography machine. The United States has requested three times but was rejected? It turns out that China’s 3D metal printing technology leads the world, and its importance is not lost to the lithography machine. No wonder foreign countries can’t buy it with a lot of money. It is useful to circle it. 3D metal printing is a basic discipline used in physics, engineering and technical science , Scientific instruments in the field of mechanical engineering. In the field of mechanical processing, China started relatively late. In the industry, there is a term called standardization, that is, the components of industrial products are produced by the same process, which requires the use of machine tool Read more

3D Printing Service And Device In China

One weekend morning, a small 3D printing technology demonstration was being held in a cafe where entrepreneurs gathered in Haidian District, Beijing. The organizer is Tiertime Technology Co., Ltd., the largest portable 3D printer manufacturer and 3d printing China. This time they brought 8 desktop 3D printers with a height of only 13 cm. This event attracted many technology enthusiasts and technology enthusiasts. Many people brought their own 3D works, hoping to “print” these works with 3D printers. The printing process is very simple. The experiencer only needs to connect the printer to his own laptop through the USB interface, download the drawing software from the official website of Tyre, and import the 3D graphics file on the drawing platform; then start the printer, and the “ink” – ABS will be printed. After the plastic coil is installed on the printer, the computer will automatically import the 3D data into Read more

Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

The Ministry of Environmental Protection recently issued the “Guidelines for the Best Available Techniques for Electroplating Pollution Prevention and Control (Trial)”, which provides technical basis and guidance for the industry to improve its technological level, carry out pollution control and related environmental supervision. The technical guide first analyzes the treatment technology of process pollution prevention, wastewater treatment, spray tower electroplating waste gas, dust removal, wastewater sludge treatment and disposal, and points out the advantages and disadvantages of various main treatment technologies and their scope of application. On this basis, various best available technology combinations were put forward, and its process parameters, pollutant reduction and emission, economic applicability, etc. were clarified around the technology, and as many as 44 technical application considerations were also proposed, which has strong Guidance. The pollution produced by the electroplating process includes water pollution, air pollution, solid waste pollution and noise pollution, including water pollution (mainly Read more

The new standard changes the ecology of the electroplating industry

As one of the four basic manufacturing processes, electroplating is widely used in various industries, such as high-end electronics, aviation, aerospace, energy, nuclear industry, low-end daily hardware, auto parts, stationery products, etc. Replaced service industries. According to incomplete statistics, in 2009, the number of electroplating enterprises (enterprises above designated size) in my country totaled 15,000, with more than 5,000 production lines and a production capacity of 250 to 300 million square meters of electroplating area. In recent years, with the remediation of heavily polluting enterprises by local governments, the number of electroplating enterprises has been on a decreasing trend. In 2008, the Ministry of Environmental Protection promulgated the “Emission Standards for Electroplating Pollutants” (GB21900-2008). The promulgation of the standards provides a basis for the management of key industries and key pollution sources. What problems does the new emission standard encounter? Need to find a balance between compliance with investment and Read more

Electroplating wastewater treatment process and principle of heavy metal removal

In terms of the total amount of electroplating wastewater, such as papermaking, printing and dyeing, chemicals, pesticides, etc., the amount of water is small, and the pollution surface is narrow. However, due to the wide distribution of electroplating plants, there are many types of highly toxic substances in the wastewater, which is very harmful. Untreated electroplating wastewater discharges into rivers and ponds and seeps into the ground, which will not only harm the environment, but also pollute drinking water and industrial water. Electroplating wastewater contains heavy metal ions such as chromium, zinc, copper, cadmium, lead, and nickel, as well as highly toxic impurities such as acid and alkali cyanide. Some are also highly toxic substances that cause cancer and distortion. Therefore, they must be dealt with carefully to avoid harm to people. (1) Typical process flow (2) Principle of heavy metal removal Generally, heavy metal ion removers can be used Read more

Research and Analysis of the Recent Development of the Electronic Accessories Market

In recent years, the sales of smart terminals have achieved rapid growth, but experts suggest that this growth rate will gradually slow down. The glorious thing is that the electronic accessories market, which is dominated by smart terminals, has gradually gained momentum, continuing the prosperous scene of the electronic market. Brands and channels, as the two legs of market sales, have always been the focus of electronic product manufacturers. Offline channels are not without opportunities. Entering large shopping malls and offline stores that emphasize experience will become the main battlefield for high-end brand electronic products. Electronic product brand Ten-year cycle of domestic brands, innovation and upgrading. The market share of electronic products in my country has increased this year, especially in the smart terminal market. At present, domestic brands have entered the high-end smartphone market. Relevant data shows that in the first half of 2013, domestic brand smartphone sales reached Read more

Trends that the hardware mold industry needs to understand to keep up with the international pace

The mold manufacturing industry occupies a special position in the product manufacturing system, and its development level determines the overall level of the manufacturing industry. my country’s mold industry started late, and there is still a lot of work to be done if it wants to catch up with the pace of the international mold industry. Improving yourself is the first step. 1. Creativity and innovation for development Creativity and innovation are the eternal theme of an enterprise, and innovation is the foundation for the survival and development of an enterprise. Luo Baihui, head of the International Mould and Metal Plastic Industry Suppliers Association, said that companies in the metal and plastic industries across the country will carry out design innovation activities under the guidance of the association. The association will continue to guide enterprises to use scientific and technological progress and innovation as the support for the transformation of Read more

Inventory of new trends in auto parts technology

Achieving the diversification of injector injection models is also the future development trend of manifold injection technology. For example, in the design of the bending angle of the spray cone, engine developers can flexibly adjust the shape of the injector spray cone to make it compatible with the The geometry of the airway is compatible to avoid wall wetness, thereby controlling hydrocarbon emissions. The Injector Active Safety TRW manufactured by Continental has integrated active safety technology. TRW, which has been committed to active safety systems, brought a series of active safety technologies at CES, including traffic jam assist, highway automatic driving, emergency steering assist, and pedestrians. Protection, etc., and these functions are based on the support of cameras and radar sensors. The S-Cam 3 camera can cooperate with the ACC function at high speed, adding some monitoring functions. The S-Cam 4 camera includes a three-lens camera with a telephoto lens Read more

- ABS Machining

- Ceramic Machining

- PA6 Machining

- PAI Machining

- PC Machining

- PCTFE Machining

- PEEK Machining

- PEI Machining

- PET Machining

- PI Machining

- PMMA Machining

- PP Machining

- PPS Machining

- Teflon Machining

- PU Machining

- PVC Machining

- PVDF Machining

- UHMW Machining

- UNILATE Machining

- POM Machining

- PTFE Machining

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal

- Research and Analysis of the Recent Development of the Electronic Accessories Market

- Trends that the hardware mold industry needs to understand to keep up with the international pace

- Inventory of new trends in auto parts technology

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal