Start clamping

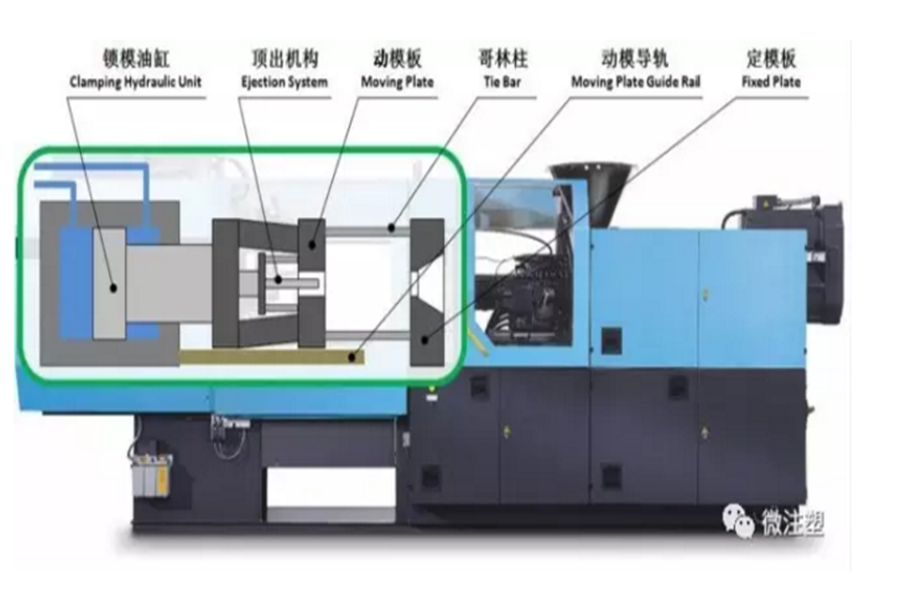

1. Start clamping pressure: The initial setting value is 25. When the pressure is too small and the speed is too slow, you can try to increase the speed. This pressure is too small, and the speed cannot be increased to the speed when needed. The speed is increased by +5 each time. Try and pay attention that when the pressure is set to a large value, the movable template will be instantly increased by high pressure to change the static state and become moving, so that the movable template hole and the tie rod will generate huge friction, which will accelerate the wear of the machine’s movable template hole and tie rod for a long time. The stability and precision of the movement of the movable platen decreases, which may affect the production of individual molds with higher precision requirements for the clamping mechanism.

2. Starting mold clamping speed: It depends on the actual situation, but it should be noted that the action should not be too fast. The speed should be a continuous movement with the next mold clamping action, instead of an obvious pause action switch. It is best to set the speed to high and the pressure The setting is low, and the speed is controlled by the pressure.

Low pressure clamping

Push the mold at low pressure and low speed, from the distance that needs safety protection to the complete closure of the mold

1. Low-pressure mold clamping speed: According to the actual situation, the speed should be slow or too fast. Even if low pressure is set, the inertial motion still has a huge impact and destructive force. The sliding position shifts quickly, the thimble breaks out…

When there is an unexpected hard obstacle, it will enter the plastic mold clamping action. Under the effective low pressure and slow mold clamping protection parameter conditions, the impact damage can be greatly reduced. In fact, the speed can be several tens, and then do not move it, and then start to adjust the pressure very low, such as 5 for testing, control the speed with pressure, and then increase the pressure step by step to a suitable clamping protection speed.

2. Low-pressure mold clamping pressure: You can adjust the speed to a very high first, and the pressure to be very low. For example, 5 for mold clamping test, because the pressure is low, even if the speed is set too large, and the pressure is not supported, the clamping speed will not be very high. Fast, control the speed by pressure. On the basis of 5, add a little bit to the ideal clamping protection speed, and close the mold with the lowest pressure.

3. The starting position of the low pressure mold clamping: (that is, the ending position of the mold clamping in the previous section) This should be set according to the size and structure of the mold with a large difference in size, generally between 5-20 cm before the mold is closed. This position is for everyone to see Write. Many people just set the mold to close too close, and then start to use low pressure. The distance that should be protected by low pressure in advance is affected by the previous larger pressure speed. The mold is closed, the sliding position is shifted, the thimble is broken, … When a hard obstacle is hit, the low-voltage protection is invalid, and it is too late. (Key core),,,,

4. End position of low pressure mold clamping (ie the start position of high pressure mold clamping): This parameter is the position where the mold is just completely closed, that is, the moving template has reached the end and stopped. When debugging, adjust the low pressure and speed first, and then set the position Set to 0, the manual mold clamping test with the door closed will get a low-pressure mold clamping fully closed position value;

For example, this value is 2.2. The size of this value is affected by the adjustment of the electronic ruler, the tightness of the mold adjustment, and the size of the clamping pressure, and this value will be affected by the accuracy of the machine and the influence of small debris on the mold surface. Each time the mold is closed, it may be affected. There will be small changes, so the end position should be set a little larger, such as adding 0.2 to 2.4 (refer to adding 0.1-0.3) to accurately protect the mold at the lowest position.

If you don’t set the position value obtained by the low-pressure mold clamping test to be a little larger, just use 2.2. It may often happen that the low-pressure mold clamping position is greater than 2.2, and the low-pressure position cannot be ended and cannot be switched to the high-pressure mold clamping. However, more people are setting the mold and there is a distance of a few centimeters or longer, and the low pressure is not completely closed.

After the termination, the high pressure is used, and the low pressure protection is invalid. It is often seen that some molds are accidentally brought out by accidents and the formed products are closed, and the steel mold cavity is compressed and deformed.

Three, high pressure mold clamping

Begin to use a high-pressure pusher to hinge and straighten the closed mold lock. Many people just set the mold to be not completely closed, and then start to use high pressure, and the low pressure protection fails (key core),,,,

1. High pressure clamping pressure: the initial setting value is 60, when it cannot be satisfied, the pressure is +10 each time, the pressure is too large, it is not necessary to increase the machine load…

2. High pressure clamping speed: The initial setting value is 25. When the need cannot be met, first try to increase the pressure to check, and then try to increase the speed, +10 each time. High-pressure mold clamping should not hear too much noise, the speed is doubled, and the friction loss of the mold clamping mechanism is increased by N times.

Everyone should pay attention

The difference between mold clamping and mold clamping I mentioned above is that mold clamping = moving template movement, mold clamping = use a high-pressure pusher to hinge, straighten and lock the closed mold, and the low-pressure mold-clamping protection setting. In fact, most people are clamping the mold at low pressure. The start position and the end position are not right. First, when the low pressure start position, the mold is too close, the position is too small, the low pressure protection comes too late, and it is subject to the higher and faster pressure of the previous section (start, fast, high speed). Speed influence.

The second is that the low-pressure termination position ends too early. When the mold is still a few centimeters or more away from being closed, the low-pressure protection is terminated and the high-pressure mold clamping is switched. These two problems generally exist at the same time, which becomes a low-pressure closure. If the mold protection position is too short, it is threatened by the impact of greater pressure and rapid mold closing before being pressed by the high pressure clamping pressure on both sides, which is equivalent to the invalidation of low pressure mold clamping protection.

Under ineffective low-pressure protection, the following problems may occur when the mold is compressed or crashed. The obstacles are entrained and the plastic mold is closed at a higher pressure = the mold and the hard obstacles are entrained at a higher speed. The mold is closed = the mold is hit)

1. Due to the simple structure of the mold, the clamping pressure is not very large, and the pressure is not broken.

2. The mold is compressed, which reduces the precision of the mold, changes the molding conditions of Plastic Machining molding, and makes it more difficult to debug the uhmw machining process parameters.

3. The mold is compressed, which reduces the precision of the mold, increases and increases the burrs of the formed product, increases the work intensity and workload of the production workers, accelerates the fatigue of the workers, and decreases the output, quality, and efficiency of the product. . The degree of liking for work is declining, and the turnover of employees may increase a little as a result.

4. The mold is pressed, which reduces the precision of the mold, which increases the burrs of the formed product. The originally scheduled personnel can no longer meet the labor needs of the work, and it is necessary to increase the manpower to make the labor-intensive production of products, the labor is more intensive, the labor expenditure is increased, and the production cost of the product is increased.

5. The mold is crushed and hit, causing the mold to be damaged and unable to produce, delaying production, and it takes time and expense to repair the mold.

6. The smooth surface of the mold cavity is hit and crushed. No matter how it is repaired, it is difficult to avoid leaving a patch mark and leaving a mark on the formed product. There is a repaired mark on the smooth surface of the product. This is a flaw in the United States, and the quality and grade of the product may be affected.

7. The mold is crushed or damaged. Welding, connecting and repairing bad molds. The quality and performance of molds are deteriorating rapidly, and the incidence of mold breakage is increasing, which increases the cost of mold operation and maintenance. With the gradual decrease of repair, replenishment and precision, the service life of the injection mold will eventually be damaged by accidental impacts due to the fact that it is not properly protected in production, and the final life will be shortened.