When the production is over or the quality of injection molding fails, the injection molding machine needs to be shut down temporarily or for a long time. How to do the shutdown work is not only related to the quality of the next molding and the loss of raw materials, but also affects the service life of the screw and barrel.

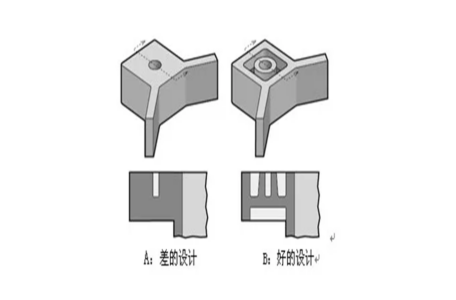

Key points of plastic machining structure design

The whole process of a product from research and development to the market needs to go through many links, among which the product structure design is an important part. In terms of product structure, the product must be manufactured and mass-produced with a mold for the product, and a plastic mold for plastic parts. Therefore, a product structure design engineer must not only be familiar with the structure of plastic parts, but also have a certain understanding of plastic molds. Today I will share with you 14 key points of plastic product structure design~

Introduction of three types of plastic molds

Plastic molds are tools used with plastic molding machines in the plastic processing industry, and can provide complete structural configurations and precise dimensions for plastic products. According to different molding methods, plastic molds can be divided into the following three types. 1.Injection mold Injection molds are often used to produce thermoplastic parts, and the corresponding processing equipment is injection molding machines.

Three principles that need to be met for mold material selection

Mold material selection is a very important link in the entire mold making process. Mold material selection needs to meet three principles: The mold meets the work requirements of wear resistance, strength and toughness; The mold meets the process requirements; At the same time, the mold should meet the requirements of economic applicability. The mold meets the requirements of working conditions

Plastic Injection Mold Manufacturing And Production Process

The plastic injection mold production process is generally divided into: customer customization, mold design, mold manufacturing, mold inspection and testing, mold modification and repair, mold maintenance, and I will explain them one by one below. Customer Customization In the production of plastic molds, customer engineers first provide product drawings to the mold manufacturer. The manufacturer collects, analyzes, and digests product data through the task requirements of molded plastic production, which is customized for customers.

The Increase And Decrease Technology Of Prototype Production!

- ABS Machining

- Ceramic Machining

- PA6 Machining

- PAI Machining

- PC Machining

- PCTFE Machining

- PEEK Machining

- PEI Machining

- PET Machining

- PI Machining

- PMMA Machining

- PP Machining

- PPS Machining

- Teflon Machining

- PU Machining

- PVC Machining

- PVDF Machining

- UHMW Machining

- UNILATE Machining

- POM Machining

- PTFE Machining

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal

- Research and Analysis of the Recent Development of the Electronic Accessories Market

- Trends that the hardware mold industry needs to understand to keep up with the international pace

- Inventory of new trends in auto parts technology

- Intrinsic Viscosity Of Polyetheretherketone (PEEK)

- The Development Of 3D Printing In China

- Advantages Of 3D Printing Technology In China

- 3D Printing Service And Device In China

- Guidelines for Best Available Techniques for Electroplating Pollution Prevention and Control Released

- The new standard changes the ecology of the electroplating industry

- Electroplating wastewater treatment process and principle of heavy metal removal